Table Of Contents

- Introduction: The Grocery Game-Changer You Didn't Know You Needed

- The Evolution of Instacart's Item Availability Prediction Model

- Breaking Down the Challenges: Why Prediction Isn't Simple

- The Heart of the System: The G-T-R Hierarchical Inventory Availability Model

- Powering It All: Real-Time Data Pipelines and Infrastructure Overhaul

- Real-World Wins: Case Studies and Impact on Customers

- Overcoming Hurdles: Techniques for Sparse Data and Interpretability

- Cost Savings and Scalability: The Engineering Edge

- Looking Ahead: Trends in Predictive Analytics for Grocery

- FAQs

- Conclusion:Why This Matters for the Future of Shopping

Introduction: The Grocery Game-Changer You Didn't Know You Needed

Imagine you’re craving fresh avocados for guacamole, but it’s late at night, and you’re scheduling a delivery for tomorrow morning. You add them to your cart, only to see a warning: low stock. Frustrating, right? But what if the system knew those avocados would be restocked by dawn? That’s the magic behind Instacart’s real-time inventory prediction system—a powerhouse of machine learning that keeps your shopping seamless.

In the fast-paced world of grocery delivery, where supply chains twist like a pretzel during holidays or storms, predicting what’s on shelves isn’t just helpful; it’s essential. Instacart handles hundreds of millions of items across thousands of stores, using predictive analytics for grocery item availability to ensure you get what you want. This system doesn’t just guess; it learns from millions of shopper scans daily, turning data into decisions that save time, reduce waste, and boost satisfaction.

We’ll dive deep into how this scalable real-time product availability system works, from its hierarchical structure to cost-saving tricks. Whether you’re a tech enthusiast, a retailer eyeing efficiency, or a shopper tired of substitutions, stick around. By the end, you’ll see why accurate predictions are the unsung heroes of your next delivery.

The Evolution of Instacart's Item Availability Prediction Model

Back in the day—think pre-pandemic—Instacart’s original model did a solid job. It crunched data every few hours, predicting if an item was in stock, low, or out. But as catalogs exploded and customer habits shifted, cracks appeared. More people planning ahead meant predictions needed to flex for future deliveries, not just now.

Enter the upgraded Instacart item availability prediction model. Built on machine learning for real-time inventory prediction, it tackles volatility head-on. During COVID, inventory swung wildly—remember the toilet paper shortages? Instacart’s team saw the need for something smarter, more interpretable, and cheaper to run.

Key stats paint the picture: Instacart processes millions of shopper signals daily, but their catalog is hundreds of times larger. That means sparse data for many items. The new model? It cut costs by 80% while improving accuracy, thanks to strategic scoring schedules. No more blanket updates; frequent items get hourly checks, while rare ones update daily.tech.instacart.com

This isn’t just tech talk—it’s about real impact. Accurate predictions cut order cancellations by up to 20% in similar systems, per industry reports from McKinsey. For Instacart, it means happier customers who stick around, with retention rates potentially rising as trust builds.

Breaking Down the Challenges: Why Prediction Isn't Simple

Predicting availability sounds straightforward, but it’s a beast. First, interpretability: If the model says an item is out but it’s not, why? The old setup made debugging tough, leading to missed restocking cues.

Then there’s sparse data. Post-pandemic, catalogs ballooned, but signals didn’t keep pace. Most items have few observations, making guesses unreliable.

Business mismatches add fuel. Customers ordering for later need future-focused predictions, while shoppers picking now want current intel. One score doesn’t fit all.

Finally, legacy infrastructure dragged things down. Batch jobs every 2-4 hours meant stale data and high costs for massive scales.

Instacart’s solution? A fresh take on machine learning infrastructure for retail availability, blending real-time data streaming for inventory predictions with smarter modeling. It’s like upgrading from a bicycle to a sports car—faster, more efficient, and way more fun to handle.

The Heart of the System: The G-T-R Hierarchical Inventory Availability Model

At the core is the G-T-R model, a hierarchical inventory availability model that’s as clever as it is effective. G for General, T for Trending, R for Real-Time—each layer builds on the last for precise forecasts.

Start with General availability. This captures long-term patterns over 7-180 days. For popular items like bananas, it pulls local data from recent weeks. For rarities? It widens to national trends over months, ensuring a solid sample size. This tackles sparse data head-on, providing a reliable baseline.

Trending steps in next, spotting deviations. Using XGBoost, it analyzes recent events—think baby formula shortages or storm-driven water runs. By feeding in General scores as priors, it simplifies features and boosts accuracy. Offline tests showed superior performance, and it’s interpretable: Compare Trending to General to see event impacts.

Real-Time seals the deal, reacting to the latest signals. If a shopper marks an item out-of-stock, the model infers restock time from historical PDFs (probability distribution functions). It only scores items with recent observations (within 10 hours), slashing costs since that’s just 1% of the catalog.

This structure shines in inventory forecasting for large scale grocery delivery. It’s not just accurate; it’s adaptable, powering everything from cart building to shopper routing.

Powering It All: Real-Time Data Pipelines and Infrastructure Overhaul

Behind the model is a revamped pipeline, ditching Snowflake batches for Griffin, Instacart’s MLOps suite. Real-time data streaming for inventory predictions means signals hit the system in minutes, not hours.

Stratified scoring is key: Head items (1% with recent signals) get hourly Trending and Real-Time updates. Torso items (85%) update daily, tails even less. Result? 80% cost savings without skimping on quality.infoq.com

The API supports multiple versions, too. Logistics gets fresh scores for routing; customers get future-oriented ones for scheduling. It’s like having a crystal ball tailored to each need.

Trends back this up: Gartner reports real-time analytics can cut operational costs by 30% in retail. For Instacart, it’s about optimizing customer experience with product availability data, turning potential frustrations into seamless shops.

Real-World Wins: Case Studies and Impact on Customers

Picture this: A family in Texas preps for a hurricane. Water flies off shelves, but Instacart’s system detects the trend early, warning users and suggesting alternatives. No panic buys, fewer cancellations.

In experiments, the new model lifted business metrics—fewer “not found” reports, higher fulfillment rates. Customers see indicators like “low stock” (as in the app screenshot), prompting smart choices.

For retailers, it’s gold. Better predictions mean informed restocking, reducing waste. One partner saw a 15% drop in overstock issues after integrating similar tech, per a Bain & Company study.digitalCommerce360.com

Tips for others: Start with data hygiene—clean signals are crucial. Scale gradually; test hierarchical models on subsets. Tools like XGBoost and streaming platforms (Kafka-inspired) make it doable.

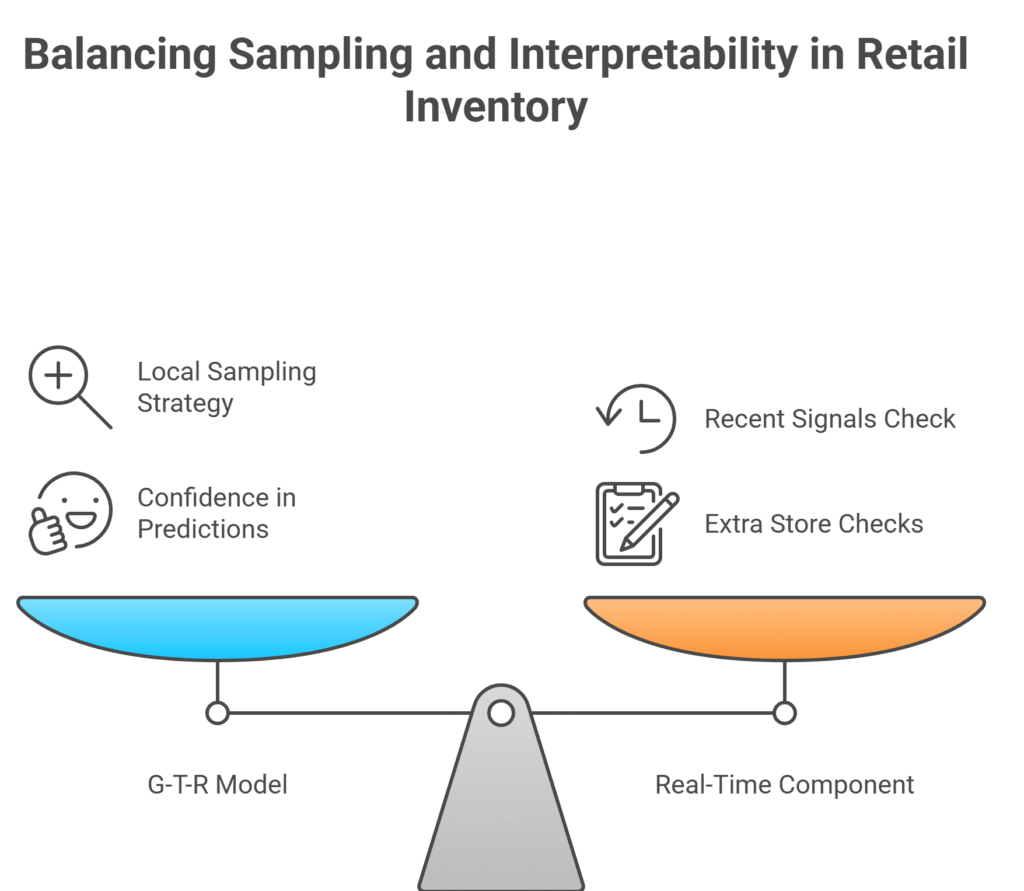

Overcoming Hurdles: Techniques for Sparse Data and Interpretability

Sparse data? The G-T-R model’s sampling algorithm searches locally first, expanding as needed. It’s principled, ensuring confidence in predictions.

For interpretability in machine learning for retail inventory, compare components: If Real-Time drags the score down, check recent signals. This prompts actions like extra store checks.

Current trends lean toward explainable AI—regulations like EU’s AI Act push for it. Instacart’s approach aligns, building trust in predictions.

Cost Savings and Scalability: The Engineering Edge

Scaling to hundreds of millions of items? The pipeline’s efficiency is key. By limiting Real-Time to fresh signals, compute drops dramatically.

Machine learning reduces costs and latency in Instacart’s inventory system through smart scheduling. It’s a blueprint for others: Event-driven streaming architecture in inventory prediction handles bursts without breaking the bank.

Benefits abound: Lower latency means fresher data, cutting cancellations. Can real-time inventory predictions reduce order cancellations? Absolutely—studies show up to 25% drops in e-commerce.

Tools for building scalable product availability models

XGBoost, Griffin-like MLOps, streaming platforms like Apache Kafka.

Machine learning consulting for grocery delivery platforms

Seek experts in retail AI for custom hierarchical setups.

Software solutions to optimize real-time inventory visibility

Cloud-based ML platforms like AWS SageMaker or Google Vertex AI.

Looking Ahead: Trends in Predictive Analytics for Grocery

Grocery delivery’s future? More AI integration. Hierarchical models are efficient for large-scale inventory prediction, per recent NeurIPS papers.

Should retailers adopt Instacart’s machine learning approach to inventory forecasting? If scale’s your game, yes. It balances accuracy with costs.

Is real-time availability prediction critical for grocery delivery services? In a word: vital. With e-grocery hitting $250B by 2025 (Statista), precision wins market share.

Overview of Instacart’s multi-model experimentation framework for availability

It involves offline evaluations, A/B tests, and iterative tweaks for optimal performance.

Benefits of event-driven streaming architecture in inventory prediction

Faster responses to changes, lower costs, and seamless scaling during peaks.

Improving interpretability in machine learning for retail inventory

Component comparisons reveal prediction drivers, aiding quick fixes.

Techniques for handling sparse data in real-time product availability

Smart sampling: Start local/recent, expand for sample size.

Best practices for implementing real-time inventory prediction systems

Clean data first, use scalable tools, test hierarchies, monitor costs.

What is Instacart’s real-time inventory prediction system?

It’s a machine learning-driven setup predicting item availability in real-time, using shopper signals and retailer data for millions of products.

What machine learning models power Instacart’s item availability predictions?

Primarily XGBoost in the Trending layer, with statistical methods in General and inference in Real-Time, all under the G-T-R framework.

What challenges does Instacart face in real-time product availability forecasting?

Sparse data, interpretability, business mismatches, and legacy costs— all addressed in the new system.

How does Instacart predict real-time availability of millions of products?

Through the G-T-R model: General baselines, Trending deviations, and Real-Time inferences, scaled via efficient pipelines.

How does the G-T-R hierarchical model improve inventory prediction accuracy?

By layering long-term, recent, and immediate data, it handles sparsity and provides interpretable, context-aware scores.

Can real-time inventory predictions reduce order cancellations?

Yes, by flagging issues early, allowing alternatives and cutting surprises.

Should retailers adopt Instacart’s machine learning approach to inventory forecasting?

Absolutely, for scalability and cost savings in large operations.

Is real-time availability prediction critical for grocery delivery services?

Essential—it drives efficiency and customer satisfaction in volatile markets.

FAQs

Conclusion :

Why This Matters for the Future of Shopping

Instacart’s real-time inventory prediction system isn’t just tech—it’s a lifeline for modern grocery. By weaving machine learning for real-time inventory prediction with smart infrastructure, it delivers value at scale. Customers win with reliable carts; retailers with efficient ops; Instacart with growth.

As trends evolve, expect more innovations like this. Dive in, experiment, and see how predictive analytics for grocery item availability can transform your world.CareerSwami.